contact us

Add(Factory):3A, Huanyuan East Road, Lechang Industrial Transfer Park, Shaoguan City, Guangdong Province

Add(Sales Center): F1503, Kingdom Plaza Center, Dongcheng Middle Road, Dongguan, Guangdong, China

Tel:+86-0769-22361118

Fax:+86-0769-22361116

E-mail:sales@hgfrp.com

FRP flat panel is the product item HIGOAL made huge investment on developing, with the characteristics of resistance to corrosion, mould, humidity and electricity, etc.

HIGOAL FRP panel has a significant advantage, that is easy-cleaning. Gel coated FRP panel is exceptionally resistant to scratch, negligibly effected on by blood, detergents and bleach disinfectant. FRP gel coat panel is the ideal hygienic panel.

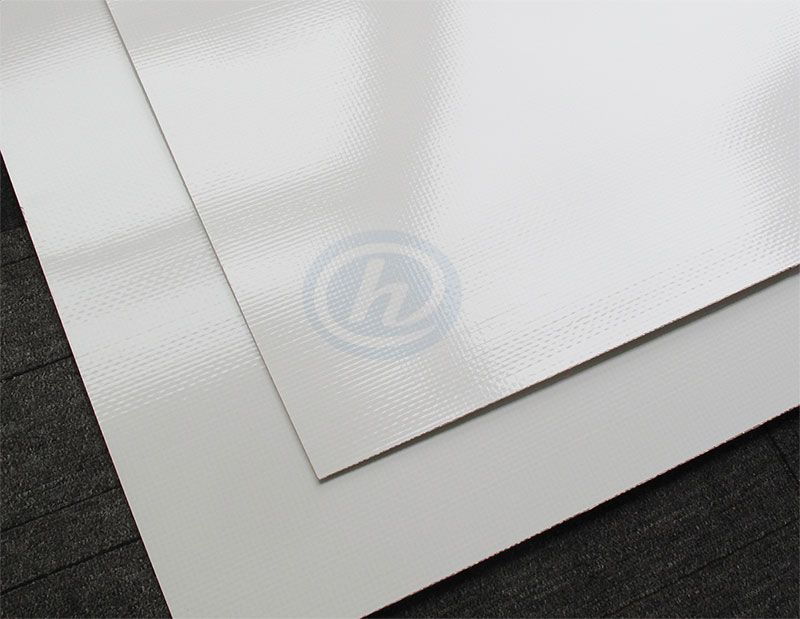

Higoal FRP Fabric Pattern Sheet:

HIGOALFRP Fabric Pattern Sheet:

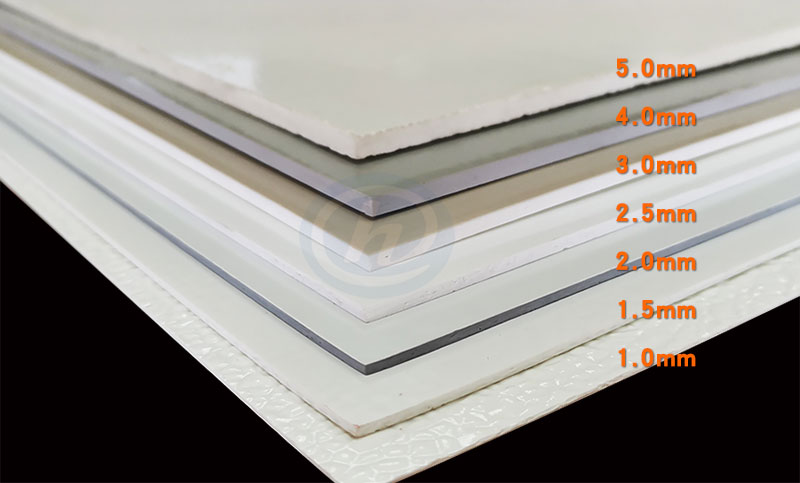

Standard thickness: 1.2mm/1.5mm/2.0mm/2.5mm/3.0mm

Customized thickness: 1.0mm/ 4.0mm/ 5.0mm

Standard color: white,creamy,grey etc.

Customized color: RAL color.

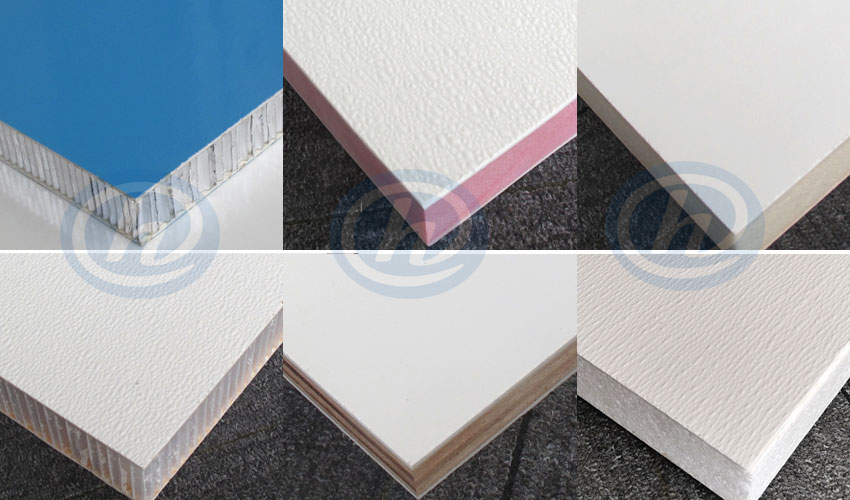

FRP panel can be combined as sandwich panel, with XPS core, gypsum, plywood, PP and aluminum honeycomb, etc.

FRP flat panel is continuously made, can be produced into sheets or rolls according to the specific requirement. The standard sheet size is 1220x2440mm, and panel rolls is 100-400m per roll ( the thinner panel will be packed with longer length as roll, the thicker panel will be packed with large roll core, and less length)

.jpg)

When the thickness is more than 3.5mm, it is not convenient to roll, so it is recommended to make in sheets.

There is a gel coat layer without glass fiber on the surface of FRP panel, which makes the product more rigid, and glossy, better perform in appearance and UV and yellowing resistance. With the gel coat, the gloss of panel is well retained to enhance the weathering-proof property. As there is no glass fiber contained in gel coat layer, the surface toughness is relatively poor. It might be cracked, when the panel suffer from excessive tensile strength, specially during making sandwich panel.

Some factors cause FRP gel coat panel cracks:

1. Bending diameter: FRP panel contains reinforced glass fiber fabric, which makes it different from common thermoplastic. Its bending diameter must be larger than 500mm, or it may crack.

2. Impact: Manufacturing the sandwich panel, if there is protruding spot, such as sand grain or other substance, it will easily crack during combining.

3. Loading & unloading, and transporting: It should not be bent during moving the FRP panel, or would easily damage the products.

Higoal use automatic machinery to roll up FRP panel, and is strict and experienced on packing and transportation. There is no possibility of panel breakage before delivery. Therefore, Higoal do not accept any returned panels after unrolling, unless a reasonable statement is presented.